- 0755-21675210

- acdrive@micno.com.cn

La serie ke600a se desarrolló sobre la base de ke300, con una mayor funcionalidad y adaptabilidad a aplicaciones más complejas:

integra el control vectorial de circuito cerrado, el control vector sin sensor, el control V / F, el control rectángulo y la función de inicio suave,Se han utilizado ampliamente en esferas como las máquinas de devanado de gran precisión, las imprentas, las imprentas, etc., que exigen gran precisión y precisión.

y la tarjeta de expansión de impulsos según sus necesidades reales.

respuesta dinámica rápida 1234 4567890 control de vector sin sensor, tiempo de respuesta dinámica & lt; 20 ms;

control de vector cerrado, tiempo de respuesta dinámica & lt; 5 Ms.Es fácil responder a la tensión tormentosa.Motores de paso remoto (1230,89 Hz, vector de carga baja, 1230,89 Hz, carga baja, 0,67 Hz),Un apagón transitorio del 200% activado por un momento (Motor de paso de control vectorial cerrado) de 123.567.890, con una capacidad de apagón instantáneo de 123.567.890, garantiza que el sistema no salte de las compuertas durante el corte instantáneo.El regulador automático de 1.234.567.890 avr de 1.234.567.890 voltios mantiene automáticamente la estabilidad de la tensión de salida al introducir las fluctuaciones del voltaje.El MERIT vector de circuito cerrado controlado por el sincrónico

tiene un excelente control vector de circuito cerrado y puede producir una salida rectangular alta a una velocidad de cero, con una relación de velocidad de 1: 1.000.

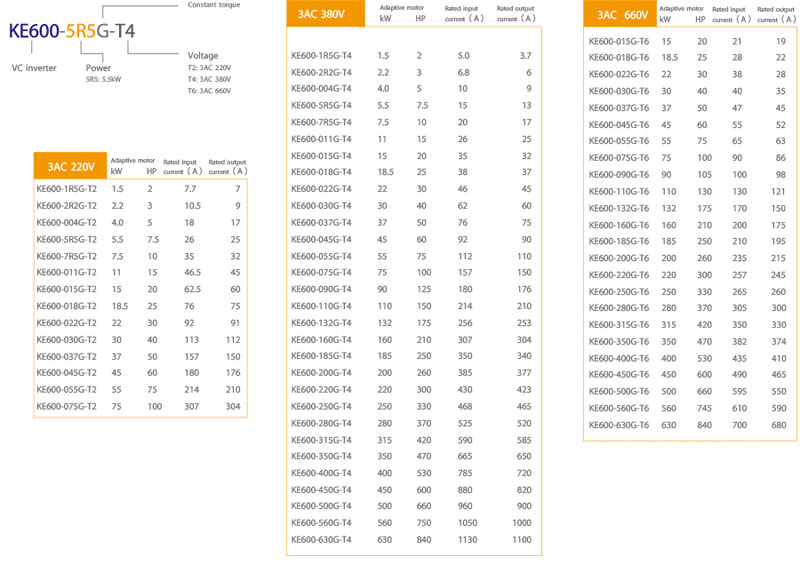

| Input | Input voltage | 3AC 220V±15%, 3AC 380V±15%, 3AC 660V±15% |

| Input frequency | 47~63Hz | |

| Output | Output voltage | 0~Rated voltage |

| Output frequency | V/f:0~3000Hz, VC:0~300Hz | |

| Control | Control mode | V/f , SVC, VC, Torque control |

| Feature | Operation command mode | Keypad control, Terminal control, Serial communication control |

| Frequency setting mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined & switched in various modes. | |

| Overload capacity | 150% 60s, 180% 10s, 200% 3s. | |

| Starting torque | 0Hz/180% (VC); 0.5Hz/150% (SVC) | |

| Speed adjustment range | 1:1000 (VC); 1:100 (SVC) | |

| Speed control precision | ±0.5% (SVC); ±0.02% (VC)) | |

| Carrier frequency | 0.5--16.0kHz, automatically adjusted according to temperature and load characteristics | |

| Frequency accuracy | Digital setting: 0.01Hz | |

| Analog setting: maximum frequency ×0.05% | ||

| Torque boost | Automatically torque boost; manually torque boost 0.1%~30.0% | |

| V/f curve | Three types: straight line, multiple points and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | |

| ACC/DEC mode | Linear/S curve; four kinds of ACC/DEC time, range 0.1s~3600.0s | |

| DC braking | DC braking when starting and stopping | |

| DC braking frequency: 0.0Hz~maximum frequency, braking time: 0.0s~36.0s; Braking current: 0.0%~100.0% | ||

| Jog operation | Jog operation frequency: 0.0Hz~maximum frequency Jog ACC/DEC time: 0.1s~3600.0s | |

| Simple PLC & multi-step | Max. 16 steps speed running via built-in PLC or control terminal. | |

| speed operation | ||

| Built-in dual PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | |

| Automatic voltage regulation | Keep output voltage constant automatically when input voltage fluctuating | |

| Control | Common DC bus | Common DC bus for several inverters, energy balanced automatically |

| Function | Torque control | Torque control with/without PG |

| Torque limit | “Rooter” feature, limit the torque automatically and prevent frequent over-current tripping when running | |

| Wobble frequency control | Multiple triangular-wave frequency control, special for spinning | |

| Timing/length/counting control | Timing/length/counting control function | |

| Over-voltage & overcurrent stall control | Limit current & voltage automatically when running, prevent frequent over-current & over-voltage tripping | |

| Speed tracking restart | Start the running motor smoothly without impact, protect the safety of motor and load at the most | |

| Fault protection function | Up to 30 fault protection including over-current, over-voltage, under-voltage, overheating, default phase, overload, shortcut, etc., can record the detailed running status during failure & has fault automatic reset function | |

| Special | Motor switching | Two groups of motor parameters to achieve two motors switching |

| Functions | Spare part | Braking parts, IO extension card, differential input PG card, open collector input PG card, injection molding machine card, communication card, etc. |

| Powerful host software | Support KE600 parameter setting and real-time parameter monitor | |

| Terminals | Input terminals | Programmable DI: 7 on-off inputs, 1 high-speed pulse input, can extend 3 inputs*1 |

| 2 programmable AI: | ||

| AI1: voltage -10~10V | ||

| A12: voltage 0~10V or current 0/4~20mA | ||

| Output terminals | 1 programmable open collector output: 1 analog output (open collector output or high-speed pulse output), can extend 1 output*1 | |

| 1 relay output, can extend 1 output*1 | ||

| 2 analog output: 0/4~20mA or 0~10V | ||

| Communication terminal*2 | Offer RS485 communication interface, support MODBUS-RTU communication protocol | |

| Human | LED display | Display frequency setting, output frequency, output voltage, output current, etc. |

| &Machine | ||

| interface | Multifunction key | QUICK/JOG key, can be used as multifunction key |

| Environment | Ambient temperature | -10℃~40℃, derated 4% when the temperature rise by each1℃ (40℃~50 ℃). |

| Limit | Humidity | 90%RH or less (non-condensing) |

| Altitude | ≤1000M: output rated power, >1000M: output derated | |

| Storage temperature | -20℃~60℃ | |

| Storage atmosphere | Indoor, without direct sunlight, dust, corrosive gas, combustible gas, oil smoke, vapor, drip, salt, vibration, etc. |

LEAVE_MSG